Introduction

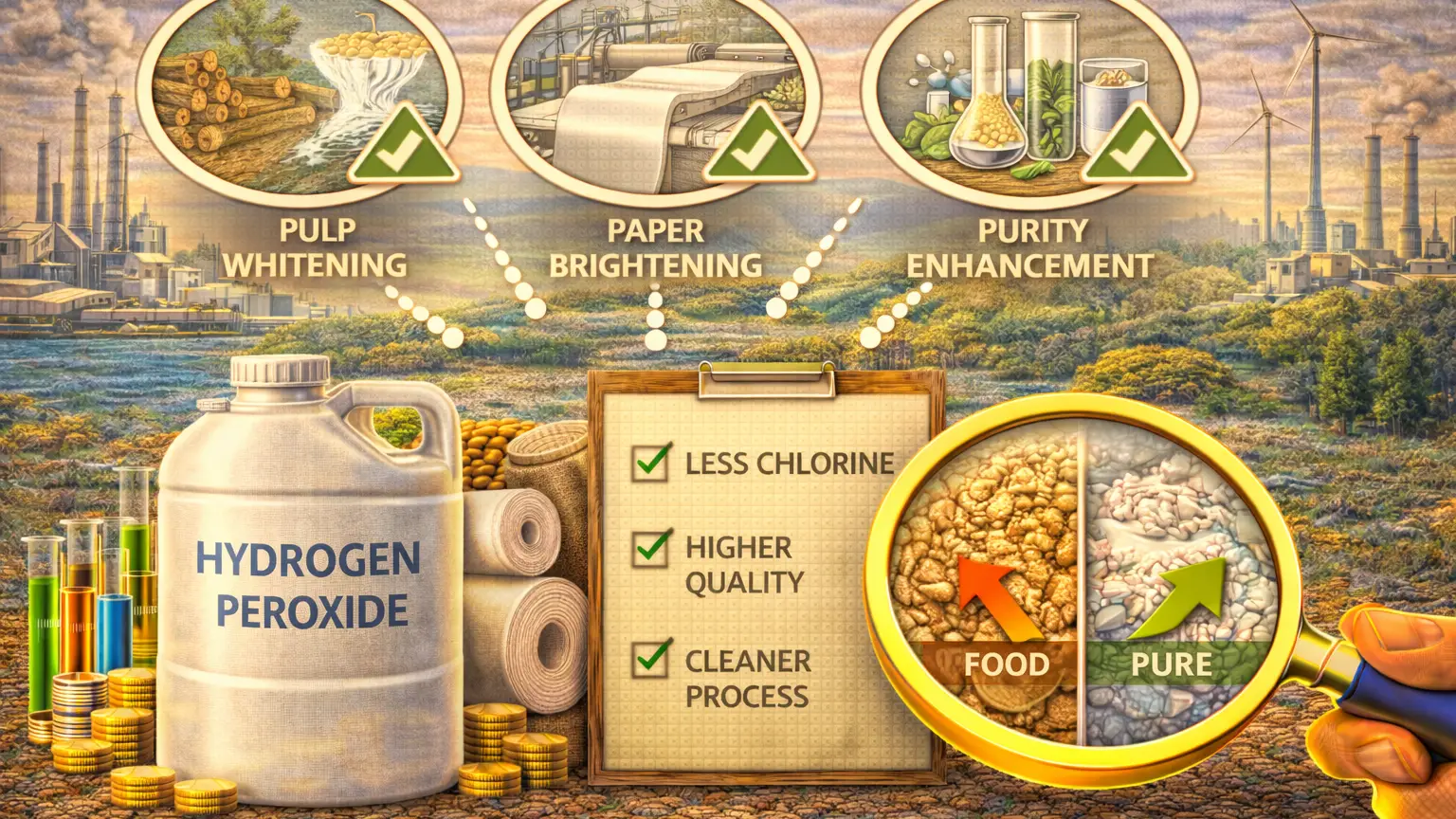

The pulp and paper industry in America has undergone a profound transformation over the past three decades. Driven by stricter environmental regulations, rising energy and raw material costs, and customer demand for sustainably produced paper, mills have steadily shifted away from chlorine-based bleaching systems toward cleaner, oxygen-based chemistries. At the center of this shift is hydrogen peroxide (H₂O₂), a versatile oxidizing agent that enables high-brightness pulp with significantly lower environmental impact.

Hydrogen peroxide plays a critical role in both mechanical and chemical pulp bleaching sequences. It is used in dedicated peroxide stages, in oxygen delignification reinforcement, and in de-inking for recycled fiber. In North America, H₂O₂ consumption in pulp and paper has grown steadily, supported by the expansion of elemental chlorine free (ECF) and totally chlorine free (TCF) bleaching technologies. For mills seeking to meet sustainability targets and reduce adsorbable organic halides (AOX), hydrogen peroxide has become a strategic chemical.

Reliable supply and consistent quality are essential for mills that depend on H₂O₂ in continuous processes. Industrial suppliers such as chemtradeasia.com provide a range of industrial hydrogen peroxide grades tailored to pulp and paper applications, helping mills optimize bleaching efficiency, control costs, and comply with environmental regulations. Understanding how H₂O₂ works—and how to source and apply it effectively—is now a core competency for modern pulp operations in America.

The Chemistry of H₂O₂ in Pulp and Paper Bleaching

Hydrogen peroxide is a powerful yet controllable oxidizing agent with the chemical formula H₂O₂. In aqueous solution, it decomposes into water and oxygen, making it inherently attractive from an environmental perspective. In alkaline conditions, which are typical for pulp bleaching, H₂O₂ forms perhydroxyl anions (HOO⁻) that are highly reactive toward lignin chromophores and certain residual extractives. These reactions selectively break down color-causing structures without excessively degrading cellulose fibers.

In chemical pulping (kraft and sulfite), hydrogen peroxide is often used in dedicated peroxide (P) stages following oxygen delignification or as part of reinforced extraction stages (EOP). The objective is to further remove residual lignin and brighten the pulp after the bulk of delignification has been achieved. In mechanical and chemi-mechanical pulps, peroxide is the primary bleaching agent, targeting chromophores while preserving yield. Typical peroxide bleaching conditions involve alkaline pH (around 10–11.5), moderate temperatures (60–90°C), and controlled retention times to balance brightness gain and viscosity retention.

Hydrogen peroxide is also central to de-inking and recycling operations, which are increasingly important in the American paper sector. In de-inking, H₂O₂ helps break down printing inks, improves brightness, and reduces the need for optical brightening agents. It works synergistically with surfactants, chelating agents, and mechanical cleaning steps. Because H₂O₂ does not introduce chlorinated by-products, its use supports mills pursuing eco-label certifications and meeting retailer and brand-owner sustainability requirements.

Key Benefits of Hydrogen Peroxide in Modern Mills

One of the most significant benefits of hydrogen peroxide in pulp and paper bleaching is its environmental profile. Unlike elemental chlorine or hypochlorite, H₂O₂ does not form chlorinated organic compounds in the effluent. Its decomposition products—water and oxygen—are benign, helping mills lower AOX levels, improve effluent quality, and comply with stringent U.S. Environmental Protection Agency (EPA) and state-level discharge regulations. This reduction in toxic by-products also simplifies wastewater treatment and can reduce sludge handling and disposal costs.

From a performance standpoint, hydrogen peroxide provides excellent brightness stability and helps mills achieve high ISO brightness levels that meet market expectations for printing, writing, and packaging grades. When properly stabilized and dosed, H₂O₂ can improve brightness reversion resistance, leading to better long-term appearance of the final paper product. It also enables mills to reduce or partially replace more aggressive bleaching chemicals, such as chlorine dioxide, thereby lowering overall chemical consumption and corrosion risk in equipment.

Economically, the use of hydrogen peroxide can contribute to lower total operating costs. While the unit price of H₂O₂ may be higher than some traditional chemicals, its higher selectivity and reduced environmental compliance costs often result in favorable total cost of ownership. Mills can optimize energy use by integrating peroxide stages with oxygen delignification, reducing steam consumption and improving yield. Additionally, the flexibility of H₂O₂ across multiple process stages—mechanical pulp bleaching, kraft pulp brightening, and recycled fiber de-inking—allows mills to standardize on a versatile chemical supplied reliably by partners such as chemtradeasia.com.

Hydrogen Peroxide Products from chemtradeasia.com

For American pulp and paper mills, consistent supply and technical support are as important as the chemistry itself. chemtradeasia.com offers a portfolio of industrial hydrogen peroxide products designed for high-volume, continuous operations. Typical commercial grades include 35%, 50%, and 60% H₂O₂ solutions, each stabilized to ensure safe storage and predictable performance under mill conditions. These concentrations are suitable for bulk deliveries via tank truck or ISO container, as well as for intermediate storage in on-site tanks with appropriate materials of construction.

The hydrogen peroxide supplied through chemtradeasia.com adheres to stringent industrial specifications, including tight limits on heavy metal contaminants such as iron, copper, and manganese. These trace metals can catalyze the premature decomposition of H₂O₂, reducing bleaching efficiency and increasing oxygen evolution in storage and process lines. By maintaining low impurity levels and providing stabilized formulations, suppliers help mills achieve higher utilization of active oxygen, more consistent brightness, and reduced risk of unplanned downtime.

In addition to product quality, chemtradeasia.com supports mills with reliable logistics and application expertise. Bulk supply chains are configured to meet the continuous demand profiles of large integrated mills as well as the more variable needs of smaller specialty producers. Technical teams can advise on optimal dosing points, storage and handling practices, and compatibility with other process chemicals such as caustic soda, chelants, and surfactants. This combination of product quality, supply reliability, and technical service makes hydrogen peroxide from chemtradeasia.com a strategic component of modern bleaching operations.

Market Trends, Regulations, and Sustainability Drivers in America

In the American market, regulatory and market forces are both pushing mills toward cleaner bleaching chemistries. The U.S. EPA’s Cluster Rules and subsequent updates have tightened limits on dioxins, furans, and AOX in mill effluents. State-level environmental agencies and regional water authorities often impose additional constraints. As a result, many mills have invested in ECF and TCF bleaching sequences where hydrogen peroxide plays a central role. This trend is reinforced by major brand owners and retailers that specify low-environmental-impact paper in their procurement policies.

Market data over the past decade show steady growth in hydrogen peroxide consumption within the pulp and paper sector in North America, even as overall paper demand has shifted toward packaging and tissue grades. Increased use of recycled fiber, lightweight packaging, and higher brightness specifications in tissue and towel products all support higher H₂O₂ usage. Mills are also exploring process intensification and advanced control strategies to extract more value from each kilogram of peroxide, aligning with broader industry goals of energy efficiency and carbon footprint reduction.

Sustainability reporting and ESG (environmental, social, and governance) commitments are now standard for large paper producers in America. Switching to or optimizing hydrogen peroxide-based bleaching helps mills demonstrate tangible reductions in hazardous emissions and effluent toxicity. Suppliers such as chemtradeasia.com contribute to these goals by offering products that support lower-impact operations and by enabling supply-chain transparency for key chemicals. As carbon pricing, water stewardship, and circular economy initiatives expand, the role of H₂O₂ as a clean, oxygen-based bleaching agent is expected to strengthen further.

Conclusion

Hydrogen peroxide has become a cornerstone of modern pulp and paper bleaching in America, enabling mills to produce bright, high-quality pulp while meeting stringent environmental and sustainability requirements. Its selective oxidation chemistry, benign decomposition products, and versatility across mechanical, chemical, and recycled fiber applications make H₂O₂ an indispensable tool in the industry’s transition away from chlorine-based systems.

By adopting optimized hydrogen peroxide bleaching strategies and partnering with reliable suppliers such as chemtradeasia.com, mills can improve brightness stability, reduce AOX and other regulated emissions, and enhance overall process efficiency. High-purity, well-stabilized industrial hydrogen peroxide solutions, backed by strong logistics and technical support, help ensure safe, consistent, and cost-effective operation in demanding mill environments.

As regulatory pressures tighten and customers continue to prioritize sustainable paper products, the strategic importance of hydrogen peroxide will only grow. Mills that fully leverage the capabilities of H₂O₂—through careful process design, robust supply partnerships, and continuous optimization—will be better positioned to compete in an evolving American pulp and paper market that values both performance and environmental responsibility.

Leave a Comment